Services

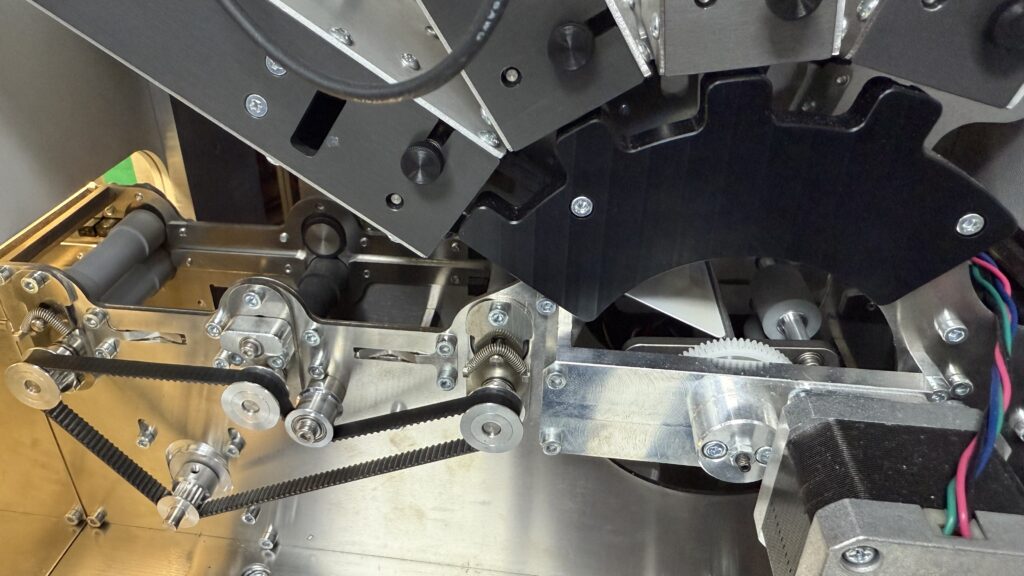

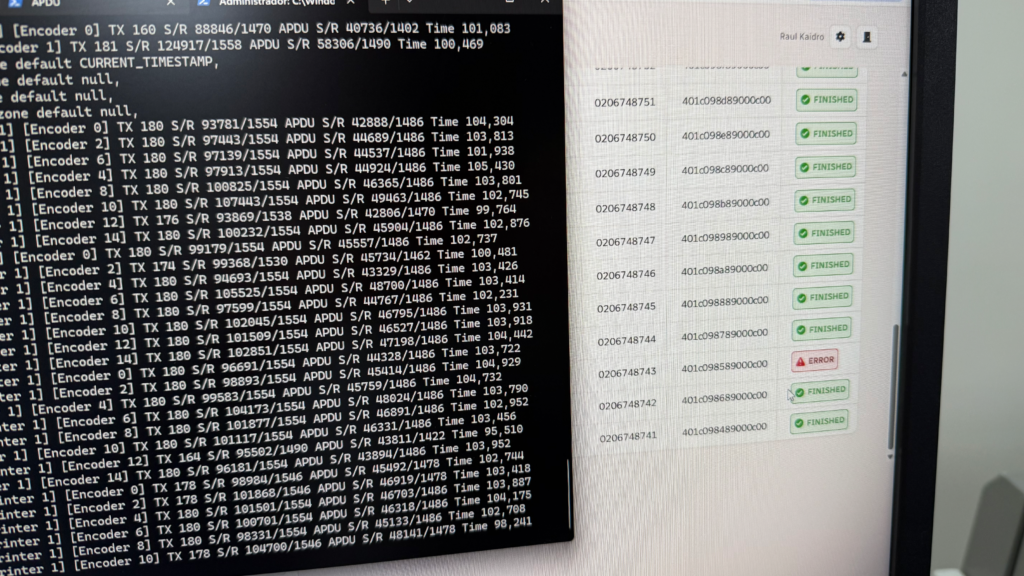

Secure identity systems built to support national infrastructure and enterprise authentication needs.

Organize, govern, and leverage critical information with tools designed for compliance and performance.

Protect digital ecosystems with advanced defense layers, threat monitoring, and expert-led risk mitigation.

Secure identity systems built to support national infrastructure and enterprise authentication needs.

Organize, govern, and leverage critical information with tools designed for compliance and performance.

Protect digital ecosystems with advanced defense layers, threat monitoring, and expert-led risk mitigation.

References

RaulWalter has worked on dozens of technically and organizationally demanding projects that have supported the development of national identity solutions, improved data quality, strengthened system security, and shaped digital ecosystems across different regions of the world.

About Us

We are RaulWalter

RaulWalter specializes in identity solutions for both public and private sector applications.